An Important Outcome of Statistical Process Control Is

Study sets textbooks questions. Both A B b.

Statistical Process Control Spc Tutorial

An important outcome of statistical process control is.

. Provide information on which areas to prioritize on to improve the process. Firms can minimize total inventory cost d. None of these c.

STATISTICAL PROCESS CONTROL METHODS 2 Summary of Process Evaluation Fruit guys have a simple procurement process. Special cause variation Selected. They highlight areas that may require further investigation.

Firms can take corrective actions before process variabilities get out of control e. SPC Statistical Process Control primarily deals with studying variation to improve process performance in. 9 On the basis of a theoretical comparison between control charts and RCTs.

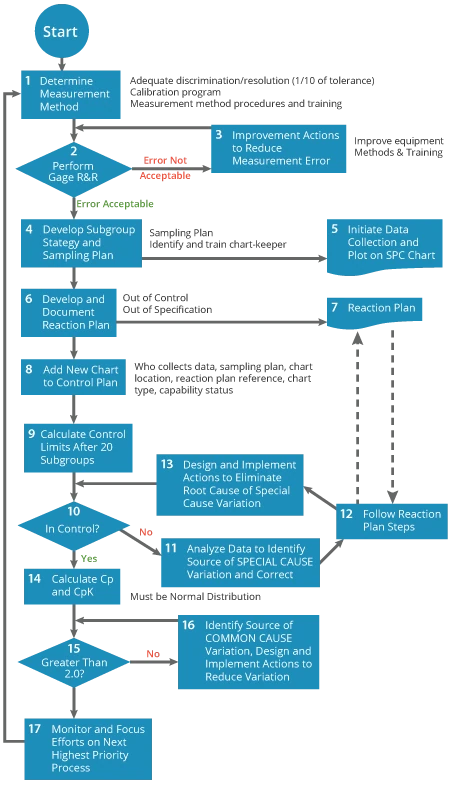

Define characteristic to measure Step 2. This process is vital since most of their products are sourced from suppliers. Firms can take corrective actions before process variabilities get out of control b.

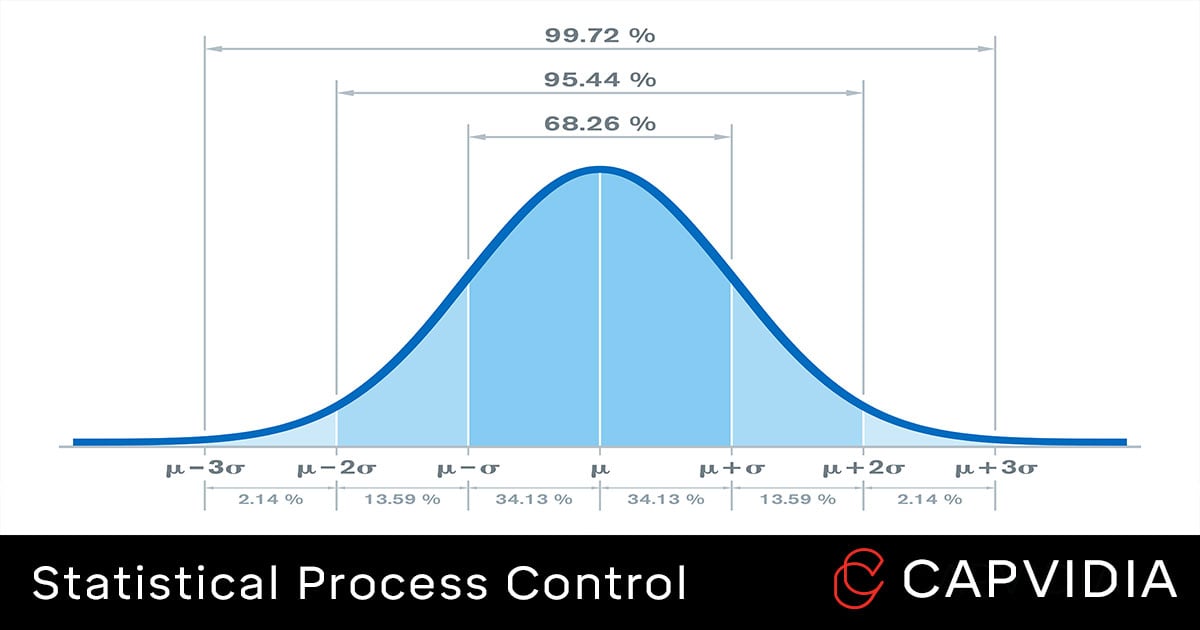

Monitoring and controlling the process ensures that it operates at its full potential. Statistical process control SPC is the application of the same 14 tools to control process inputs independent variables. The process is controlled at the right time for the right reasons and towards the right objectives.

For a company like Fruit guys. Statistical process control SPC is a method of quality control which uses statistical methods. Firms can visually monitor process performance e.

Firms can minimize total inventory cost d. Firms committing to a program of. Statistical process control lets the company control quality where it is created at source.

Firms can visually monitor process performance c. Nominal cause variation d. Statistical Process Control SPC charts are simple graphical tools that enable process performance monitoring.

They are used to identify which type of variation exists within the process. QUESTION 1 An important outcome of statistical process control is a. Statistical Process Control SPC is a statistical method to measure monitor and control a process.

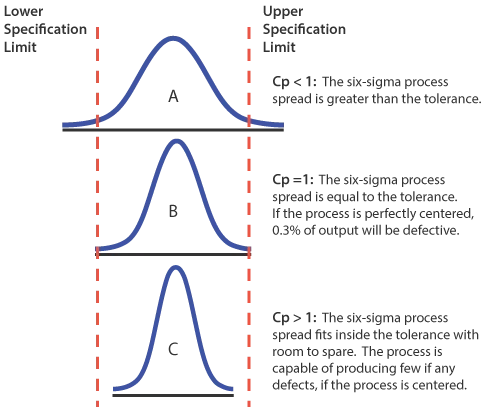

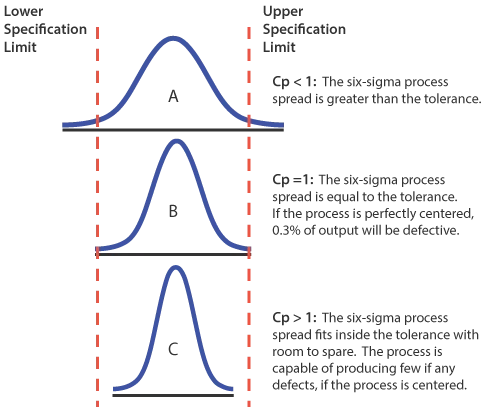

SPC produces more data quickly in a way that is more understandable to decision makers. Statistical Process Control commonly referred to as SPC is a method for monitoring controlling and ideally improving a process through statistical analysis. Statistical process control is important in that it separates special cause variation from natural variation.

Statistical process control SPC is sections of statistics that bring a series of analysis methods that are presented in a data graphic form. An important outcome of statistical process control is. An integral part of Six Sigma is.

To prevent poor product quality process improvement tool method of inspecting a sample of goods and deciding if process is in control. SPC states that all processes exhibit intrinsic variation. SPC emphasizes prevention over detection.

77 The key to this power is the statistical and practical ability to detect significant changes over time in process performance when applying SPC. Both can be produced. Statistical process control lets companies exercise control over at least one aspect of manufacturing the processes.

Using statistical process control means that instead of checking individual parts and comparing them with the tolerance limits we get a general overview of our whole process. An important outcome of statistical process control is. Heres What You Should Do Next.

None of these o d. Firms can minimize total inventory cost QUESTION 2 An integral part of Six Sigma is a. Set up control chart Step 3.

SPC charts are one of the starting points for any Lean Six Sigma project. Firms can minimize total inventory cost d. Determine whether a process is in a stable condition.

SPC is method of measuring and controlling quality by monitoring the manufacturing process where quality data is collected in the form of product or process measurements or readings from various machines or instrumentation. Take a sample and plot results. No natural cause variation.

Random success in business is due to luck. Firms can visually monitor process performance b. Firms can take corrective actions before process variabilities get out of control.

But lasting success relies on knowing how to use statistical process control to make your processes more successful more often. No special cause variationThis answer is correct. 11 Question 8 If a process is in control it has ________.

Firms can take corrective actions before process variabilities get out of control b. Why Understanding Statistical Process Control Is Important Abstract. In other words SPC is a method of quality control which employs statistical methods to measure monitor and control a process.

Firms can visually monitor process performance C. As the name suggests it relies heavily on statistical methodologies to give you an adequate overview of the current state of your production facilities and. Statistical quality control SQC is defined as the application of the 14 statistical and analytical tools 7-QC and 7-SUPP to monitor process outputs dependent variables.

The result of SPC is reduced scrap and rework costs reduced process variation and reduced material consumption. At its full potential the process can make as much conforming product as possible with a minimum if not an elimination of waste rework or. To make things worse they are operating in a highly competitive environment.

Although both terms are often used interchangeably SQC includes acceptance. Firms can visually monitor process performance. Good strategy when the process is well designed and in-control.

Reduces the opportunity for bad quality products or services to reach the customer. Statistical Process Control SPC is a commonly used technique for identifying faults in your production line and ensuring that the final product is within acceptable quality boundaries. By taking control of the manufacturing process businesses can improve quality and efficiency while managing costs.

Two of the most popular SPC tools are the run chart and the control chart. SPC is applied in order to monitor and control a process. It is a scientific visual method to monitor control and improve the process by eliminating special cause variation in a process.

Behind all lasting business success is the ability to make business processes work successfully. An important outcome of statistical process control is. The main aim of the process evaluation is to find the offer that has the most appropriate value for money.

Firms can take corrective actions before process variabilities get out of control c. In this way SPC analysis can be just as powerful and robust as study designs often deemed superior such as randomised controlled trials RCTs. Measure or inspect only a portion of the products or transactions at regular periodic time intervals.

As such it is important to understand these statistical control charts well to keep a process under control. Therefore it is essential to have a.

Statistical Process Control Spc Tutorial

Comments

Post a Comment